The Ultimate Guide to Industrial Sealing Solutions

Aug 21, 2024 Industrial seals

If you operate food and beverage equipment, heavy equipment in oil or gas, or pharmaceutical equipment driven by liquid fuels, you may agree that choosing the right seal can be daunting. If proper sealing is not used, the operating equipment may leak or be impacted by outside contaminants. The variety of choices in seals will make this selection even more challenging. Hence, it is essential to understand the different types of seals and their functions to make the right selection. This post helps you understand the same.

Get Introduced to Different Types of Industrial Seals

The following are a few common types of industrial seals for your consideration.

- Hydraulic Seals:These seals are placed in a groove or arranged in a combination of rings to separate fluids or block them in applications involving reciprocating motion, such as small motors and engines. Hydraulic seals are made from different materials, including rubber, polyurethane, and PTFE. The material can be chosen based on the type of fluid used, fluid compatibility, pressure, and temperature.

- O-rings: These industrial seals get their name from rubber-like circles placed inside the hoses, pipes, and other liquid-bearing objects. They are offered with a nozzle, cap, or valve and are designed to fit into grooves and create a reliable seal in dynamic or static applications. O-rings are widely used in food and beverage, pharmaceutical, and other industrial equipment. They are made of materials, such as EPDM, silicone, nitrile rubber, etc.

- Mechanical Seals: They are advanced sealing devices used in rotating equipment with shafts to prevent fluid leakage. Mechanical seals assure superior performance in high-pressure and high-temperature applications. This property makes them a suited choice for many challenging applications. There are different types of mechanical seals available for consideration, including balanced and unbalanced seals, pusher and non-pusher seals, conventional mechanical seals, cartridge mechanical seals, and centrifugal seals. Gaskets are also a type of mechanical seal that fills the space between mating surfaces in machines or fixtures to prevent the leakage of liquids and gases.

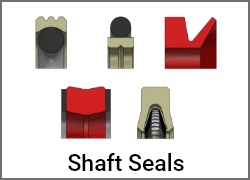

- Shaft Seals: These seals are also known as rotary seals and are designed to seal rotating shafts touched by fluids during operation. Scrapers are also a type of shaft or rotary seal.

- Piston Seals: They are a type of hydraulic seal that prevents equipment leaks. These seals also prevent wear and tear in components when they rub together. Piston seals can be designed as single-acting or double-acting seals.

- Fluid Seals: These seals are designed to prevent leaks in pipes, hoses, or round fittings. Fluid seals are also widely used in food and beverage equipment or pharmaceutical equipment.

- Power Transmission Seals: As the name suggests, these seals are used in power transmission equipment, such as lawn mower, car, and other piece of machinery. They help prevent the leakage of fuels, like transmission fluid, oil, gas, and other liquids that are exchanged in an engine or the motor. Power transmission seals are distinguished into two types – radial shaft and axial shaft. The radial shafts help contain the fluids inside the engine, whereas the axial shaft prevents the external fluids from getting into the engine.

- Tri-clamp Seals: These are one of the most advanced type of seals available for your consideration. They are widely used in food and beverage equipment and designed to fit into the groove of the seal to minimize bacterial growth.

How to Choose the Right Seal for Your Industrial Equipment

There are several considerations to be made when choosing the right seal for your industrial equipment. Here are some key considerations:

- Material Compatibility:Ensuring the compatibility between the sealing material and fluid they come in touch with is important to avoid swelling, chemical degradation, and corrosion. The seal material must be able to withstand the temperature range of the application without degradation. In addition to this, the sealing material must be compatible with the surfaces for any signs of wear and tear.

- Application Conditions:You must address the maximum pressure, speed, and environmental conditions. For instance, the maximum pressure the seal will be subjected to and need to endure without failure. If used in dynamic applications, the seal must be capable of withstanding the speed of movement of parts. Otherwise, it may be exposed to excess wear and tear. In addition to this, you must consider additional factors, such as ozone, UV light, weather conditions, particulate contaminants, and so on.

- Compliance and Standards:The seals must meet all relevant certifications and industry standards as per the regulatory requirements of your industry. For instance, if you are considering the seals for food and beverage equipment or pharmaceutical equipment then they must meet the FDA requirements. If you strictly adhere to regulatory requirements ensure to buy the seals from trusted manufacturers.

- Cost:Budget can be a constraint when investing in a good-quality industrial seal. You can always compare the initial costs with its expected lifespan and performance. Many times, an expensive seal can save you downtime and maintenance costs in the long run.

Industrial seals play a crucial role in ensuring the reliability, safety, and efficiency of industrial equipment. Businesses can make informed decisions by understanding the different types of seals and carefully considering different factors. If you are considering industrial seals for your application, ensure to partner with a trusted manufacturer like SSP Seals. The company specializes in designing and manufacturing custom seals and parts for different industrial equipment. Being a leading industrial seal manufacturer, the experts at the company understand the different application requirements across industries such as heavy equipment, oil and gas processing equipment, pharmaceutical equipment, food and beverage equipment, demolition and scrap equipment, and so on. Contact the team at SSP Seals today at phone or email.

Related Post

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote