sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

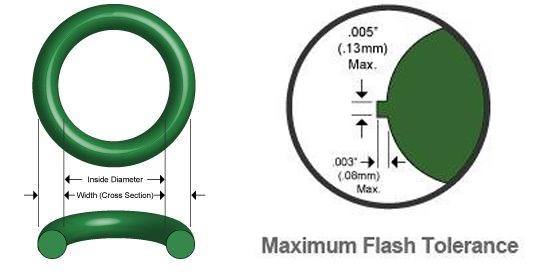

An O-ring, also known as a packing or toric joint, is a mechanical gasket in the shape of a torus. It is a loop of elastomer with a disc-shaped cross-section designed to be seated in a groove. It is compressed during assembly between two or more parts causing the interface to seal. Rubber O-rings are the most commonly used O-rings. O-ring kits are also readily available if you have varied requirements.

The O-ring may be used in static or dynamic applications where there is relative motion between the parts and O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons. O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable, and have simple mounting requirements. They can seal tens of megapascals (thousands of psi) of pressure.

We, at SSP Manufacturing have added FDA approved O-rings to our product list. These O-rings are available in several variations like:

We build strong relationships with all our clients because we provide excellent service including :

| Hardness | ISO 868 |

| Nitrile | HNBR |

| EPDM | Urethane |

| Fluorel® | Aflas® |

| Neoprene® | Hypalon® |

| Vamac® | Natural |

| Butyl | Hydrin® |

| Fluorosilicone | XNBR |

| SBR | Polyacrylate |

| Medical | Perfluoroelastomer |

To get more details about the customization process, please contact us by email at gm@sspseals.com or call toll free at +1-888-238-SEAL (7325).