sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

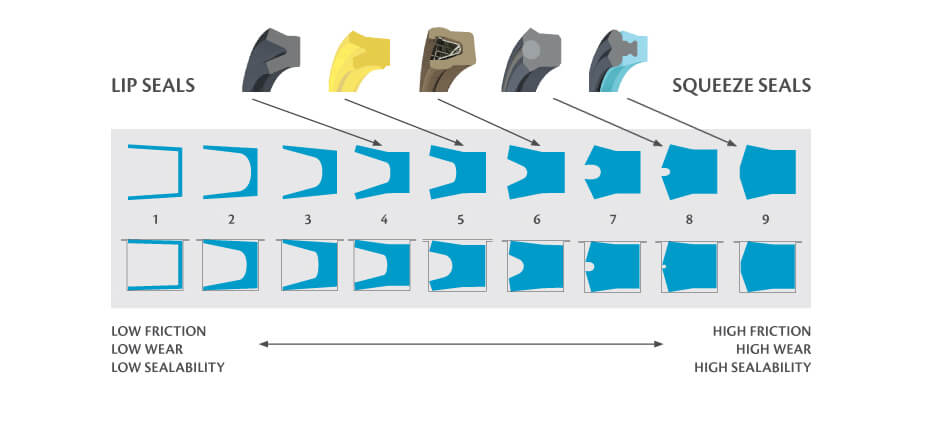

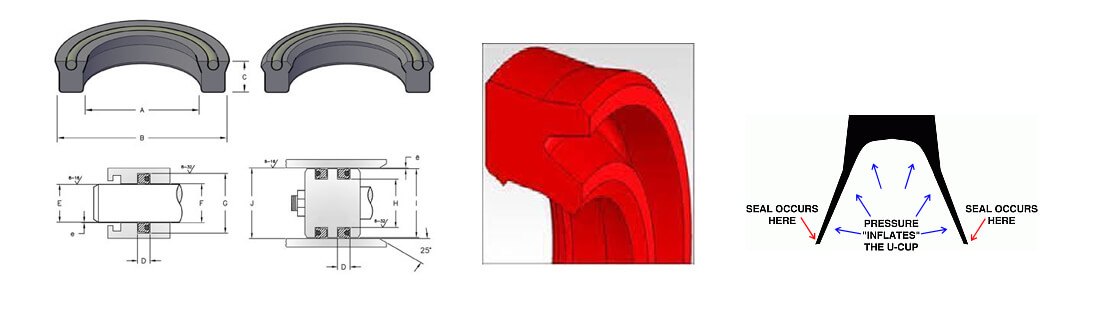

U-cup seals are named after their “U” shaped profile formed due to their distinctive cross-section. These seals are suited for high-pressure applications because the U shape of the seal energizes the seal lips at high pressures. U cup seals are ideal for static and dynamic applications. Being a leading U cup seal manufacturer, we perfectly understand client requirements and provide these seals in unique configurations. We can customize them to meet your application requirements.

The following are some standard U-seal designs provided by us.

| Loaded U-Cup Seals These seals feature an O-rings loader, which makes them an excellent sealing option for piston and rod applications. The force on the seal’s loading lips increases with the system pressure. When this happens, the sealing force compensates for the pressure automatically and maintains the sealing. It is a single-direction seal, which can pressure seal in one direction. As the sealing is unidirectional, the two U-cups must be installed in two directions for piston applications. The loaded U-cups are rectangular and this adds stability to its sealing function. |

|

| Spring Energized U-Cups These U-cups feature energized metallic spring, thus, the name. Spring energized U-cups are used in dynamic applications because the spring helps load the lips of the seal against mating surfaces. |

|

| Unloaded Urethane U-Cups This cup has no O-ring and is suited for dynamic and static applications. It is ideal for rod and piston applications and is also known as Disogrin U-cup. Unloaded U-cups are compact-sized and more appropriate for applications where small spaces are involved. Our unloaded U-cups find applications that are used in low-pressure and low-speed environments for hydraulic and pneumatic seals. |

|

| Homogenous U-Cups These U-cups are more commonly used for pneumatic applications. They are non-loaded, made from a single material, and are ideal for applications operated at low pressure. |

|

A u-cup is an o-ring formed into a u-shaped channel. Liquid or air pressure "inflates" the u-cup and affects a seal. The u-cup is ideal for use on linear moving shafts and piston heads, because unlike an o-ring the shape does not try to roll with the movement and create friction. The sides of the u-cup allow the shaft to move virtually unhindered, and seal with a wiping action.

We provide U-cup seals created from the following materials.

At SSP Seals, you can find a broad collection of U-Cup seals. Choosing the right seal for your application can be challenging at times. Several factors such as media, extrusion gap, resistance to wear and tear, and resistance to temperatures must be addressed. Here are some general factors to consider when buying these seals.

The following are some criteria to be considered when choosing a U-cup for your application.

Contact us to learn more about U-Cup seals or call +1-888-238-SEAL to get immediate answers to your question.