sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

Several industrial equipment and machinery often consist of parts, whose one component is static and the other one is rotating. In such cases, there is a risk of creation of an opening between these two components, which can hamper the overall performance of the equipment. Industrial seals are mainly used for sealing this opening. This helps save considerably on the energy costs. Different types of high-quality seals are used in a wide range of industries. Thus, seals play a vital role in a number of industrial applications. Would you like to know the applications that use industrial seals? Please read the following post to know what all applications make use of industrial seals and how.

What are the Various Application Areas of Industrial Seals?

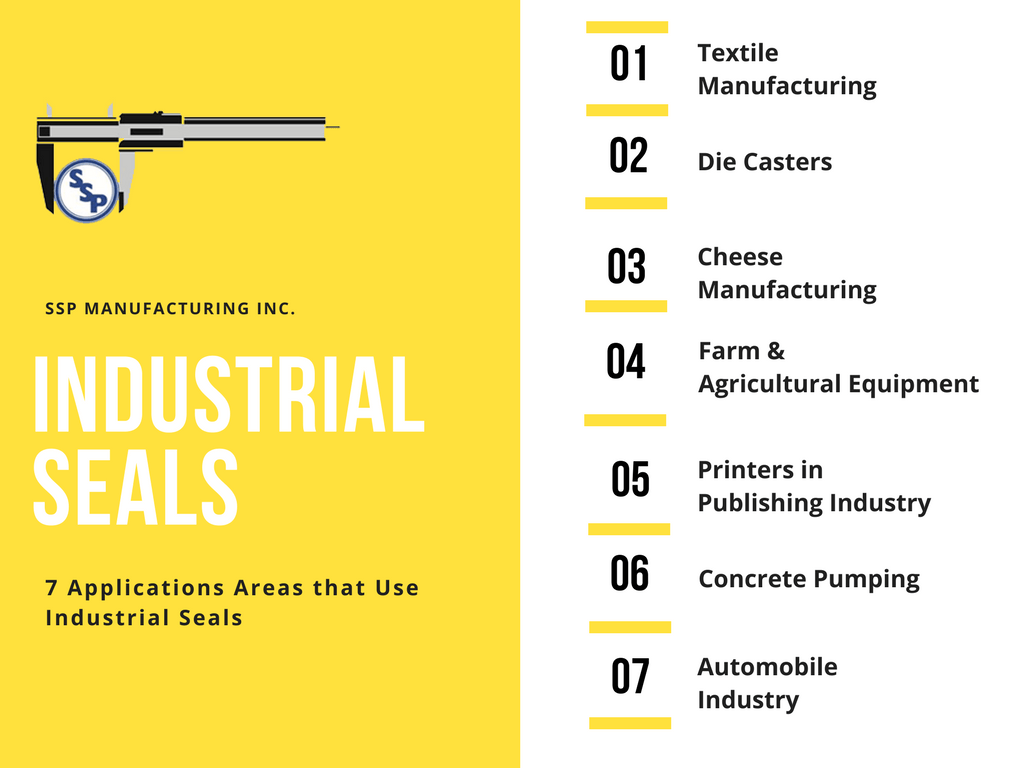

Industrial seals have a huge list of benefits, and this makes them ideal for use in a number of industries and applications. The following are some common application areas, which use industrial seals:

These are just a few most common application areas of industrial seals. It won’t be wrong in saying that seals are among the most important components used in several applications in different industries. They are extremely crucial products, and thus should always be bought from trusted, experienced, and well-known manufacturers and suppliers. SSP Manufacturing, inc. is one such leading industrial seals manufacturer in the US.

Mar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025

Comprehensive Guide to FKM Fluorocarbon Rubber: Properties, Applications, and BenefitsDec 18, 2024

Pneumatic Seals and Hydraulic Seals: Types and Materials DiscussedNov 25, 2024