sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

sales:

gm@sspseals.com

Toll Free: +1-888-238-SEAL Request A Quote

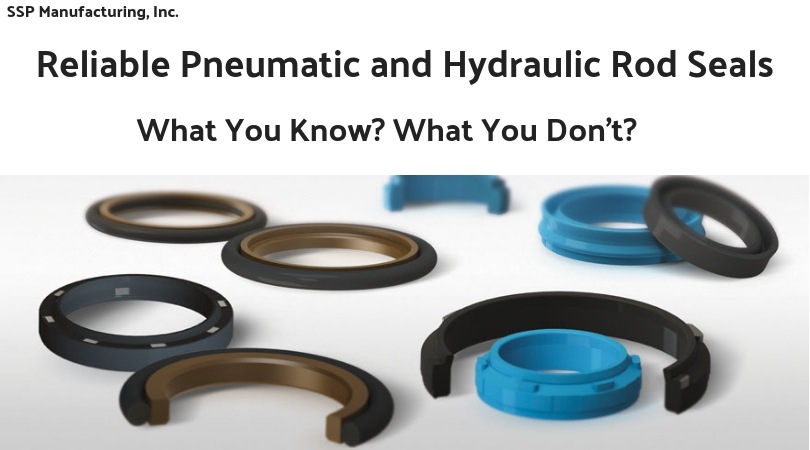

Industrial seals are popularly used in a wide range of application industries, such as pharmaceutical, automotive, heavy equipment, oil and gas, etc. The rod seals are a type of industrial seals, which are most commonly used in hydraulic cylinder systems. What are these types of seals? Are you intrigued to know more about the rod seals in detail? Well, if so, then you should consider reading the following post, as it covers all the necessary information related to these types of seals. Read on to know more.

What is a Rod Seal?

Rod seal is also sometimes referred to as a gland seal. To understand a rod seal, it is important that you understand it primary function. Preventing the leakage of pressurized fluid from the system is the primary function of a rod seal. It does not allow the internal fluid or gas to escape out into the surrounding environment by forming a seal. This is why it is considered to be the most important seal in a system. These seals play a vital role when it comes to the performance of a hydraulic cylinder.

How to Select the Right Rod Seal?

The leakage caused in this seal can lead to accidents, and hence environmental damages. Thus, it is recommended to select the right type of rod seal based on your application. Now you may ask “Are there any factors to consider while buying these seals?” Well, the answer to this question is “Yes, there are certain considerations”. The following questions will help you determine the ideal rod design and material:

Things to Remember While Using These Seals

Although these seals are being used on a large scale, still it is always advisable to be cautious while using them, in order to keep the potential hazards at bay. Most commonly, the single-acting seals are used. In these types of rod seals, the pressure acts only on one seal side from inside of the cylinder. The pressures acting on the rod side of the piston can be as high as 5800 PSI (400 bar). These pressures can be even higher at times. This is one of the factors that drive the forces between the rod surface and the rod seal. So, it is recommended to manufacture the rod surfaces matching the suggested specifications, and the materials used for rod seals should be resistant to wear.

So, this was everything that wanted to know about the rod seals or gland seals. Depending on the application for which they are to be used, there are different types of seals. S-rod seals is one such type of these seals. You can also get custom rod seals manufactured from various manufacturers. However, it is important to go with the most experienced manufacturer. One such manufacturer of high-quality seals in SSP Manufacturing, Inc. The company is known for providing consistent quality custom rod seals, and industrial seals for several years now.

Mar 28, 2025

PTFE vs. Rubber Seals: Key Differences and BenefitsFeb 26, 2025

How Seals and Gaskets Safeguard Food and Beverage Products?Feb 05, 2025

Comprehensive Guide to FKM Fluorocarbon Rubber: Properties, Applications, and BenefitsDec 18, 2024

Pneumatic Seals and Hydraulic Seals: Types and Materials DiscussedNov 25, 2024